Torque Wrenches

TORQUE WRENCHES

Torque is the rotational force that transfers the power produced in motor vehicles from the wheels to the ground. Therefore, a torque wrench is a name given to hand tools that adjust or restrict the torque in units. We defined torque as the rotational force on an axle or the system that creates this rotational force. Therefore, as a unit of torque, it is the expression in newtons of the weight created by the rotational force at the end of a one-meter arm.

A torque wrench is generally used to turn and tighten rotating fasteners such as bolts or nuts. It is generally used as a tool for twisting and pulling fastening parts. High-quality torque wrenches are mostly produced from chrome and vanadium alloy steel.

Some essential parts, such as the engine top cover and sprockets, must be tightened at a specific torque level. Such bolts should not be too loose or too tight. A torque wrench is used to fix this correct tightening value. A set screw is located on the back of the torque wrench. By turning this screw, the wrench can be brought to the desired torque value. However, the most critical point you should pay attention to while tightening the parts is gradually increasing the torque value.

Correct Application of Torque Force

When we look at many industrial applications, we see that they use the joint screw system. We can explain this system with the ability of two or more parts to be connected, to exist as a whole, and to be able to be disassembled and assembled simultaneously. The most basic principle of this system is based on the rule that the adhesion force of the parts connected by bolts is greater than the separation force on these parts due to external factors. The connecting stud is constantly under stress, hence in tension. If the applied pressure for the applied joint (pressure) is smaller than the force in the direction of separating these two parts, the screw connection will separate after a while. To achieve a reliable and long-lasting screw connection, the tension force to be applied must be made at the correct values. The only way to ensure the security of the screw joint is the controlled application of a proper torque force.

Application Example

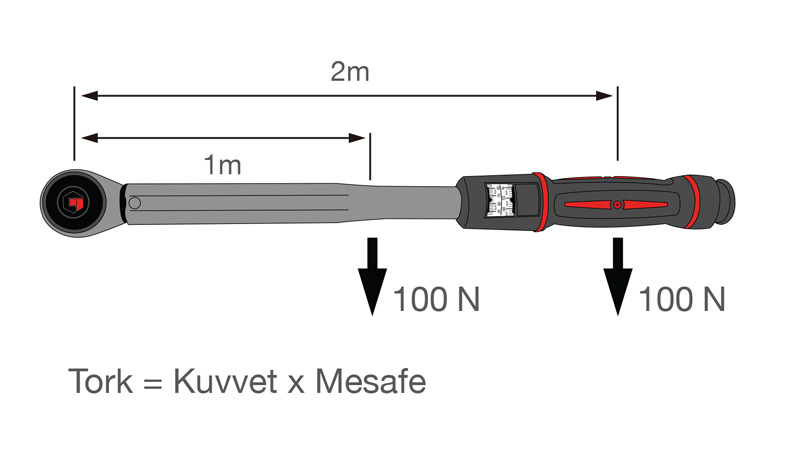

If a ten kg rotational force is applied to the nut with a 1-meter lever to tighten a bolt, the torque force applied here can be expressed as 10 kg.m or 10 N.m. As a standardized international unit of measurement, this force is called Newton.

The unit conversion of kg to N.m is: 1 N.m = 0.9807 kgf

In this case, the equivalent of the applied torque force in N.m in the example below is 98.07 N.m.

You can find the most suitable torque and torque sets for your needs here!